Manufacturer Exporter and Supplier

Disc Springs are conically formed angular discs, which are loaded in the axial direction. Disc Springs have a unique combination of high force in small spaces with customized deflection combinations.

Disc Springs offer a well-developed solution to many engineering problems. Disc Springs can be used as a single disc or arranged in stacks. A Disc Spring stack can consist of disc springs either used in Series or Parallel sets. Disc Springs are available with or without contact flats. Disc Springs are manufactured to DIN 2093 and designed as per DIN 2092. We have a custom design program to assist our customers for their specific applications. Our group 1 & 2 Disc Springs are AUSTEMPERED, this method of heat treatment is particularly effective for high fatigue Disc Springs.

Belleville washers also called conical spring washers are manufactured as per DIN 6796 & DIN 6908. Our Belleville washers are designed specifically for Heavy Duty Bolted sections such as Bus Bars, Transformers, Rectifiers, Heat Exchangers, Transmission etc. These washers are intended to counteract the effect of setting which results in bolt/nut assemblies working loose. They do not effectively prevent loosening of the assembly under varying radial load and are designed for use with short bolts predominantly subject to thrust. Belleville washers are highly stressed components and cannot be used for dynamic loading and infrequent varying load applications.

Pinakin Enterprises has ready stock of all standard sizes of Belleville washers in High Carbon Steel material, Stainless Steel 300 series and 17-7 PH. Other materials are also available on request.

Pinakin Enterprises produce Serrated Lock Washer External & Internal according to DIN 6798 & as per Customer requirements .External serrated lock washer (Type A) -The teeth are at the outer diameter of the washer which supports locking more area which reduces loosening.Internal serrated lock washer (Type J) -The teeth are at the inner diameter of the washer which is used for bolt or screw tightening.

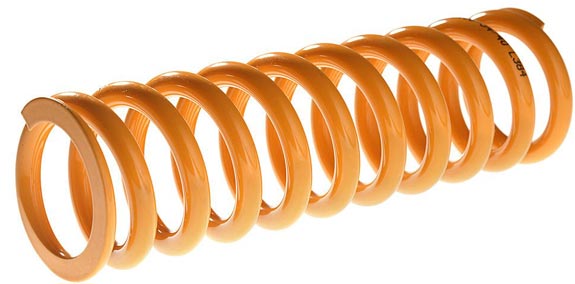

Garter Springs are helical coil springs whose ends are connected together to form a circular shape to provide a strong Radial Force. Compression garter springs exert outward radial forces, while extension garter springs exert inward radial forces.

Most of these springs are used in oil seals, shaft seals, belt-driven motors, and electrical connectors, etc.

They can easily handle pressure, viscosity, and temperature changes and prevent contamination from water, dust, dirt, lubrication, and chemicals. They can be supplied pre-assembled into loops, or in lengths – this is particularly useful for standard weights or diameters, as it allows you to cut and assemble your garter springs as needed.

Spring Materials – Spring materials include stainless steel, alloy steels, carbon steels and some non-ferrous materials. IIS also produces springs from Exotic materials like Inconel X-750, Inconel 718, Nimonic 90, Monel, Nimonic, Hastelloy, Beryllium copper etc.

Spring design – Selection of material is one of the important steps in spring Design. Types of material available, mechanical and electrical properties, operating conditions are few points of prime importance for material selection. In case of heavy stress cycles, a tight control is required in material quality. Scratches, seams and other such flaws affect fatigue life considerably. Carbon steel and alloy steel give optimum service and heavy stress cycles.

Stress Relieving – Depending upon the type of spring material – furnace temperature & soaking time will vary accordingly. Stress relieving causes dimensional distortion so manufacturer should predict the change to achieve required dimensions. Forming should immediately follow stress relieving. We have in-house heat-treatment furnaces for large diameter springs. We also strike on springs to introduce compressive stresses on the springs which help to increase the fatigue life of the springs.

Our capacity – We can manufacture compression springs of any size, length and dimension you can think of.

We have load testing machines upto 100 tons and we can test deflections up to 1200mm. Our automatic grinders can produce parallelism within 0.05mm and surface finish in microns.

We have years of experience in the manufacturing of Compression springs.

Surface coating – We offer a variety of coating on springs like Mechanical Zinc plating, Zinc Electroplating, Nickel Plating, Electroless Nickel plating, Geomet, Dacromet coating, Cadmium plating, Powder coating, Epoxy painting etc.

Tension Springs Also known as Extension Springs are helical wound Coil springs usually designed with hooks, loops or end coils. The main use of a Tension spring is to absorb or store Energy along with creating a resistance to the pulling force, the Spring gets Stretched as the Load is applied to it.We manufacture Tension Springs starting from 0.2mm wire diameter to 20mm wire diameter , OD up to 300mm and length 2000mm.

Disc springs with slots offer high deflection with low spring force characteristics required for use with small size ball bearings. The slots are around the inside diameter and help to provide axial preload, backslash compensation, absorb excessive running sound & reduce degree of stress on the bearings. Disc Spring with slots have a strong digressive characteristic which helps in constant spring force over a large deflection range. Any axial movement in the assembly also will not adversely affect the preload. We are able to achieve flatness through our special heat treatment process and full contact area helps in uniform preload.

Our curved spring washers are made of tempered steel and stainless in some sizes. All the washers are deburred using our proprietary process to achieve the best round edges for longer life. Curved Washers have distinct advantages over conventional wire springs where weight and space is concerned.

We are Manufacturing Conical Contact Washer with Tooth according to STD NFE 25-211 & Siemens SN 70093. This washer is conical shaped with tooth mounting side and top serrated side. The tooth side and serrated side of the washer exerts circular locking force at the mounting side and the internal face of the bolt head or nut. The tooth mounting side and top serrated side increases locking force and prevent the loosening of bolt during vibration & pressure.

Hot-coiled springs are generally used in elevated temperatures, high load applications or in a corrosive environment. The transportation industry, Agriculture equipment manufacturers, and construction equipment manufacturers are some of the largest users of the hot coiled springs.

Generally springs with bar diameter greater than 12.7mm (0.5 in.) are hot coiled. Bars of carbon or alloy steel are generally used for hot-coiled springs. For most hot-coiled springs, finished hardness requirement is in the range of Rockwell C 44-53.

Pinakin Enterprises can manufacture hot coiled springs up to 92mm or 3.62 inch wire diameter and OD 450mm or 17inches.

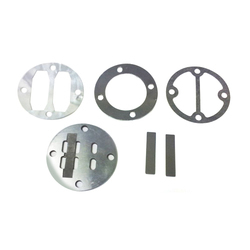

Reed Valve is a Flapper valve steel component used in different types of compressors for effective control of gas, fuel and air. Flapper Reed valves are capable of working continuously for long periods without failure. A careful & controlled manufacturing process is essential for the proper function & longer service life of a Flapper Reed Valve.

we manufacture and supply E-Clips with high end quality metals and precision machines. Quality such as high strength, perfect finish, excellent durability owing attributes durability. These are easily available at leading market prices. The most common Application is of radially fitted Circlips for shafts with grooves which provide a large shoulder on a relatively small shaft diameter.

WhatsApp us