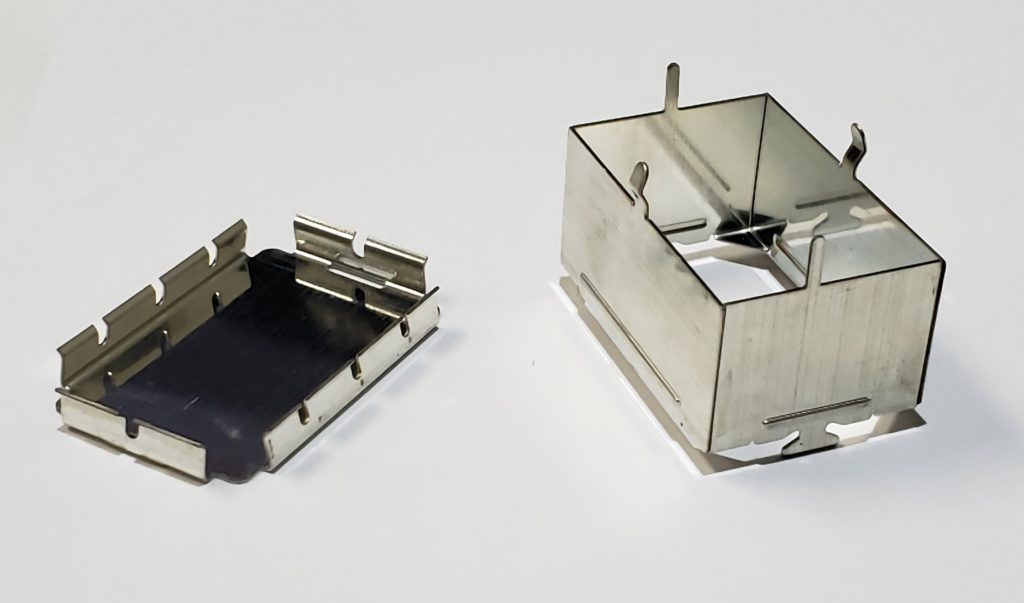

Assemblies

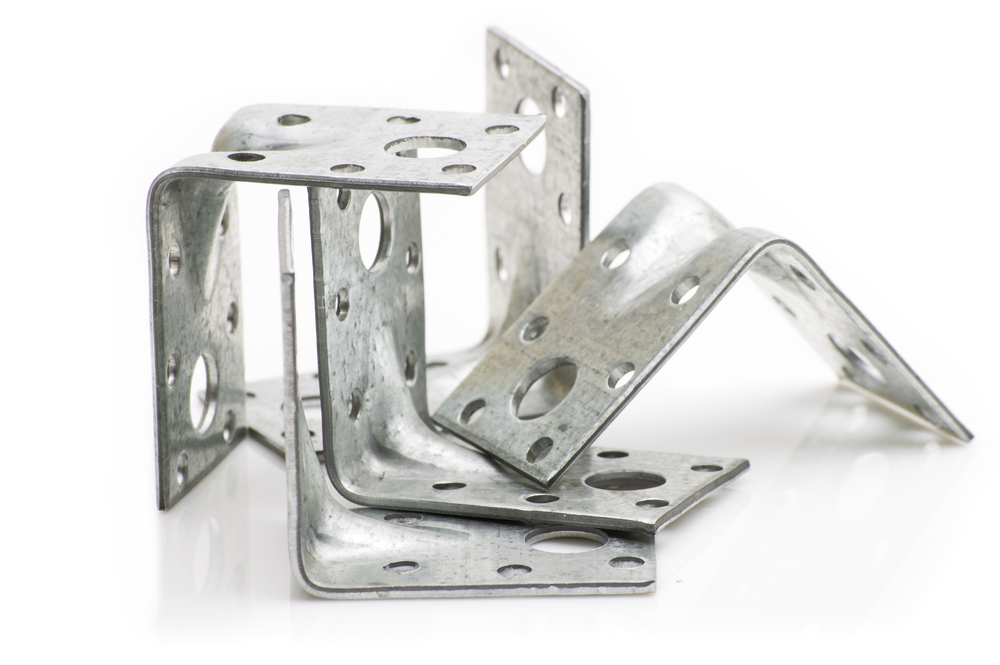

Brackets

Bushings

Metal bushings, also known as torque limiters, are cylindrical components that improve efficiency and minimize noise and vibration in equipment with rotating or sliding shafts. They ensure smooth operation in a range of high impact, high load applications, from heavy duty agricultural equipment to automotive mechanical assemblies. For optimal performance, metal bushings require accurate design specifications, careful material selection, and precision machining or stamping techniques.

Clips

Lead frames

Lead frames are manufactured by removing material from a flat plate of copper, copper-alloy, or iron-nickel alloy like alloy 42. Two processes used for this are etching (suitable for high density of leads), or stamping (suitable for low density of leads).

We produce custom lead frames in a variety of sizes and shapes. We can facilitate high volume orders of up to 30 million parts.

Metal Brackets

Shields

Pinakin Enterprises manufacture high-quality custom shields for a wide range of applications across industries.

When you choose Pinakin Enterprises for your custom shields needs, you get many benefits that include:

Tooling

High-quality tooling is usually equipped with several protection measures to ensure the longevity of the equipment. Load tonnage monitors help protect the tooling and dies from excessive impact forces, overloading, and other associated damage. They can also simplify tooling setup since planning for a known tonnage results in fewer equipment adjustments. Load tonnage monitors allow manufacturers to produce quality parts with the least amount of tonnage, thus reducing wear and tear on the tooling equipment.

Other essential protective measures, such as proximity sensors, which detect the distance of the tooling from various surfaces to help reduce the risk of crashes, heavy impacts, and damage due to equipment malfunction.

Protective measures for tooling guarantee long tooling life as well as manufacturing precision and accuracy. Quality assurance is essential in numerous fabrication methods and tooling types including:

Prototype tooling

Four-slide/multi-slide tooling

Progressive die tooling

Metal stamping